Are you a panel builder, machine builder, or

system integrator building panels?

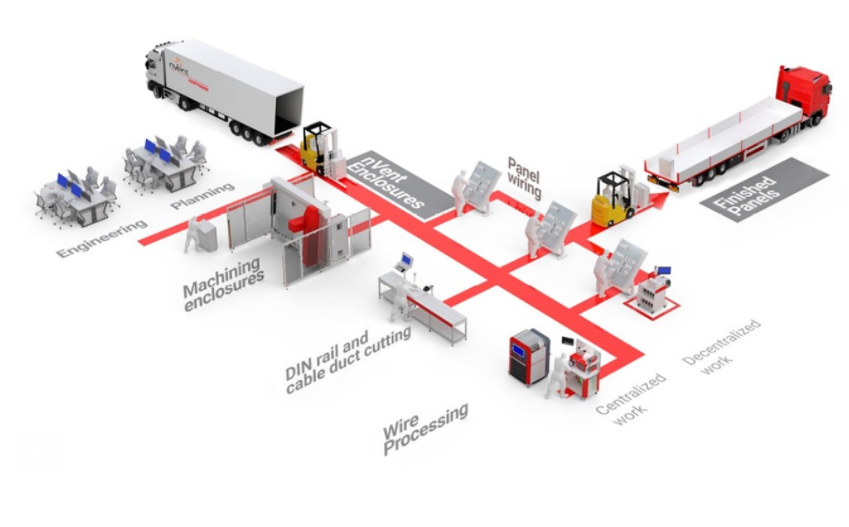

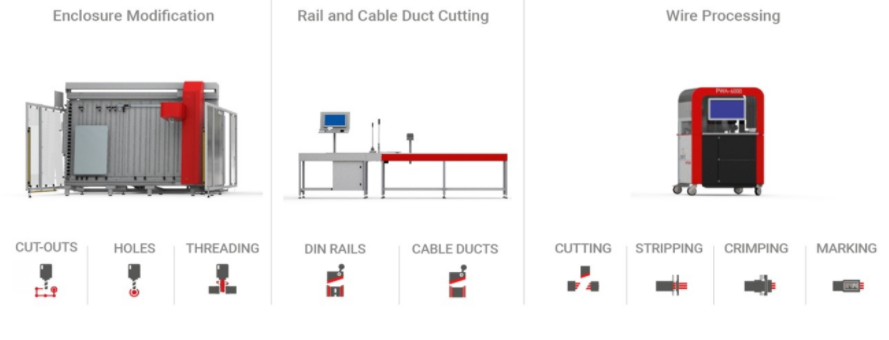

At nVent HOFFMAN we are focused on boosting your productivity and reducing your operational costs. We offer a comprehensive range of modular electrical enclosures, digital tools to support engineering, and machines for panel shop automation. If you need extra resources, Hoffman Certified Modification Centers, located at our distributors, offer rapid modification of standard enclosures. This could be especially helpful if you perhaps have staffing problems in your panel building operation due to COVID-19.

nVent HOFFMAN has the solutions you need to optimize your panel shop production. Engineering and planning tools, easy to assemble modular enclosures, plus labor-saving machines for panel shop automation will all contribute to making your business highly competitive.

Highly versatile IEC modular enclosures allow fast assembly

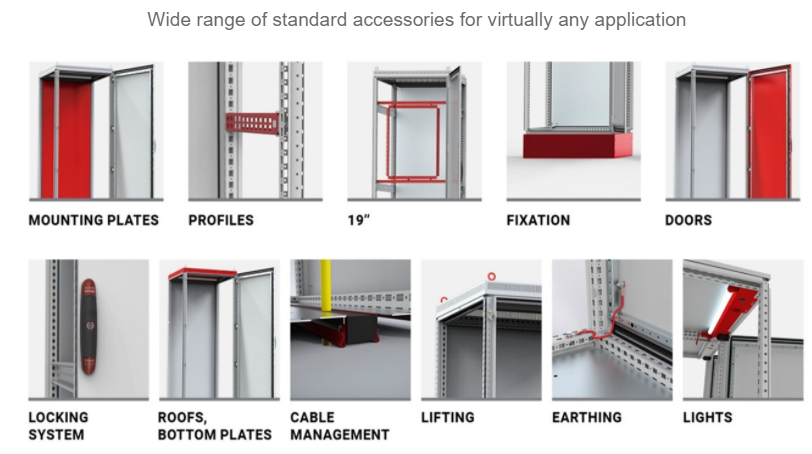

Good news! From July onwards, in addition to our NEMA enclosure ranges, we can offer a complete line of modular enclosures to meet the requirements of your customers needing IEC enclosures. The enclosures come with a wide range of accessories with one major advantage. All accessories can be mounted throughout the floor standing product line regardless of the material and construction.

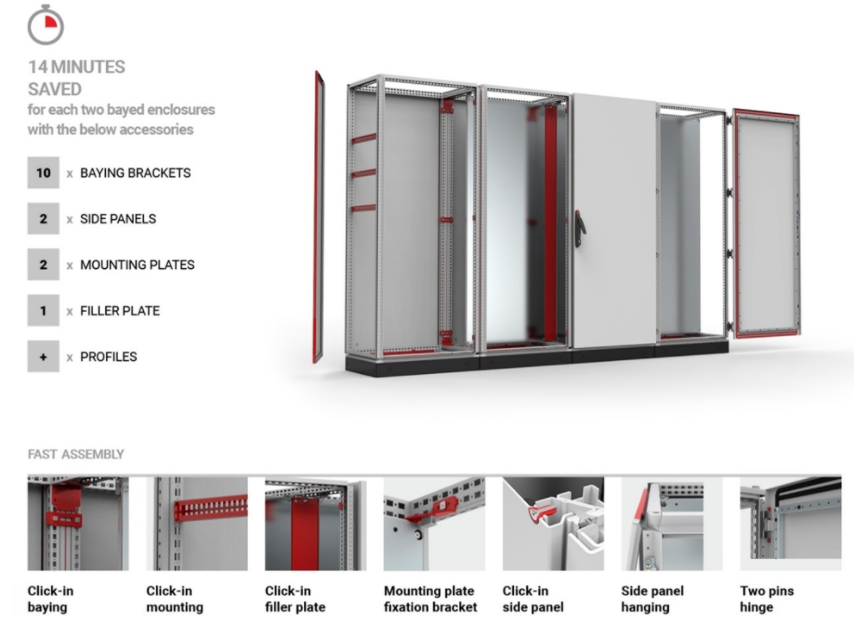

The compatibility of our accessories significantly reduces the complexity for engineers and assembly staff who work with our portfolio, ensuring fast assembly.

Our latest click-in fixation solutions are designed to give you a fast assembly turnaround and increase your competitive edge. For floor standing enclosures it is estimated that up to 14 minutes can be saved when two modular enclosures are bayed compared with traditional designs.